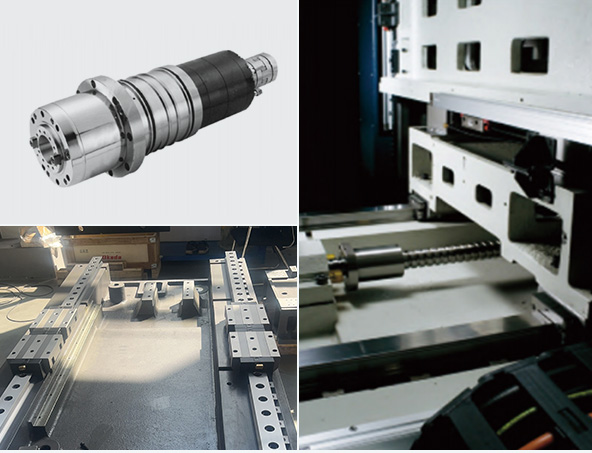

EUMA machines are built with high-strength materials and advanced manufacturing processes to ensure

durability and reliability over extended periods of operation. These machines are designed to handle high loads,

long-running cycles, and high production efficiency.