In the realm of precision manufacturing, machining centers are the workhorses that shape metal, plastic, and other materials into critical components for industries ranging from automotive to aerospace. Among the most common types are vertical machining centers (VMCs) and horizontal machining centers (HMCs), each designed to excel in specific tasks. While both are computer numerical control (CNC) machines, their core differences lie in spindle orientation, structure, and application—factors that directly impact efficiency, versatility, and cost.

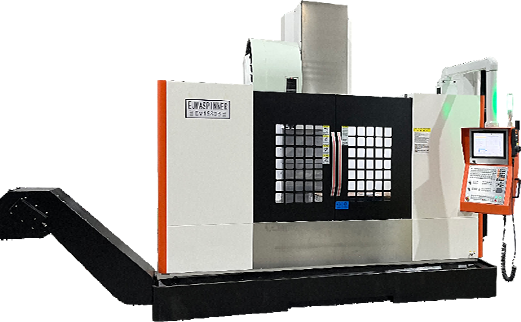

3/4 Axis Vertical Machining Center

The defining difference between VMCs and HMCs is the direction of their primary cutting spindle:

Vertical Machining Centers (VMCs) feature a vertically oriented spindle, meaning the cutting tool rotates along a vertical axis (Z-axis). The workpiece is mounted on a horizontal table, which moves along the X (horizontal) and Y (horizontal) axes to position the material under the tool.

Horizontal Machining Centers (HMCs) have a horizontally oriented spindle, with the cutting tool rotating along a horizontal axis. Workpieces are typically secured on a rotating table (often a rotary indexer or pallet changer), allowing multi-sided access to the tool without repositioning.

These spindle orientations drive key differences in their build and how workpieces are held:

VMCs have a simpler structure: a fixed or moving table (depending on the model) sits beneath the vertical spindle. Their compact footprint makes them ideal for small to medium-sized workshops. Workholding is straightforward, often using clamps or vises to secure flat or irregularly shaped parts.

HMCs are more complex, with a robust base to support the horizontal spindle and a rotating table (4-axis or 5-axis configurations are common). This design allows the workpiece to rotate relative to the tool, enabling machining of multiple faces in a single setup. Many HMCs include pallet changers, which let operators load/unload parts while the machine runs—boosting productivity.

Their designs make VMCs and HMCs suited for distinct tasks:

VMCs shine in machining flat surfaces, holes, slots, and simple 3D contours. They’re widely used for mold making, plate parts, and small to medium-sized components like brackets or gears. Their vertical spindle makes them easy to load manually, and their lower cost (compared to HMCs) makes them popular for low to medium-volume production.

HMCs excel at complex, multi-sided parts—think engine blocks, transmission housings, or aerospace components with features on multiple faces. By rotating the workpiece, they eliminate the need for repeated setups, reducing errors and saving time. This makes them indispensable for high-volume production lines where precision and efficiency are critical.

VMC Advantages: Lower initial cost, simpler maintenance, smaller footprint, and ease of manual loading. They’re versatile for general-purpose machining.

VMC Disadvantages: Limited to fewer faces per setup; chips can accumulate on the table, potentially affecting precision.

HMC Advantages: Higher productivity (via pallet changers and multi-face machining), better chip evacuation (gravity pulls chips away from the workpiece), and superior precision for complex parts.

HMC Disadvantages: Higher upfront cost, larger footprint, and more complex maintenance.

The decision between a VMC and HMC hinges on the part design, production volume, and budget. For simple parts or low-volume runs, a VMC is often the practical choice. For complex, high-volume components requiring multi-face machining, an HMC delivers unmatched efficiency.

In the end, both are vital tools—each tailored to turn raw materials into the precision parts that power modern industry. If you want to know more about CNC, you can contact EUMA Machinery, we can provide effective help

GET A QUOTE